With the enhancement of public environmental awareness and the increasingly strict requirements of environmental laws and regulations, the composition of cutting fluid has undergone great changes.The following table lists several additives that are prohibited and subject to greater restrictions:

Banned additives | Nitrite |

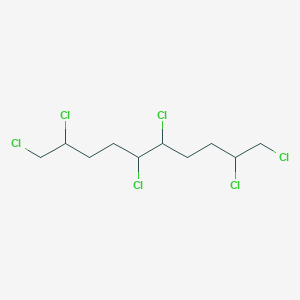

Short-chain chlorinated paraffins |

| Use additives that need to be restricted | Dicyclohexylamine |

Chromate |

Diethanolamine |

Formaldehyde-releasing bactericide |

Most of the research on environmentally friendly cutting fluid additives is still in its infancy. The following is a brief introduction to lubricants, anti-rust agents and anti-corrosion fungicides.

SCCPS are used as extreme pressure anti-wear agents in cutting fluid components. Due to their carcinogenic risks and environmental pollution after processing, their substitutes are gradually becoming a focus of attention.

Short-chain chlorinated paraffin 2D structure

SCCPS in 3D form

At present, organic borate, polyester, fatty acid ester, polyacrylamide, alkyl fatty acid and other alternative substances have been reported. Organic borate as a lubricant additive has a lot of research, with non-toxic, non-volatile, extreme pressure lubricity, and both anti-rust, antibacterial, anti-virus and other functions, is a special two-ion surfactant substances, these make borate additives, as a multi-functional additive in cutting fluid, its application is more and more extensive.

Rust prevention agents are mainly water soluble and oil soluble two categories.

Water-soluble additives include sodium nitrite, benzotriazole, boric acid, triethanolamine, phosphate, phosphate, sodium benzoate, sodium molybdate and anhydrous sodium carbonate. They interact with the metal to form an insoluble dense oxide film on its surface, preventing the electrochemical corrosion process of the metal. This kind of anti-rust agent is mostly electrolytes, when used in emulsion, the amount should not be too large, its application is more mature, or toxic or high price, poor compatibility, difficult post-treatment, there is a trend of being replaced.

Oil-soluble rust prevention agents are mainly sulfonates, ester alcohols, amines, phosphate esters, such as petroleum barium sulfonate, zinc naphthenate, heptadenyl imidazoline, dodecenyl succinic acid and so on. They are highly polar compounds, which can prefertively adsorb on the metal surface or chemically react with the surface to produce a protective film, inhibit oxygen and water and metal contact, but it will compete with the extreme pressure agent on the metal surface, causing the polarity of the cutting fluid to decline.

At present, the research of anti-rust additives mainly focuses on the combination of molybdate, borate and carboxylic acid alkyl amide, phosphate and carboxylic acid, maleimaric acid alkyl amide, cyclohexanol hexamhosphate, acrylic polymer and so on.

In general, molybdate is a non-toxic, pollution-free environmental protection additive, but the price is more expensive, affecting its further promotion and use; Organic phosphorus containing rust inhibitors have a certain corrosion effect on copper and its alloys, and can also lead to eutrophication of water, so the development of low phosphorus or no phosphorus rust inhibitors is the main development trend.

三、ANTISEPTIC AND FUNGICIDE

Antiseptic fungicides are generally used in water-based cutting fluid, water-based cutting fluid mostly contains proteins, minerals, carbohydrates required for microbial growth and reproduction, when the cutting fluid is prepared with raw materials containing mineral oil, animal and plant oils, inorganic salts and other components, it is easy to deteriorate. It can effectively kill and inhibit microorganisms by adding antiseptic and fungicide. In recent years, due to the increasingly strict environmental regulations, the commonly used phenol and formaldehyde release fungicides are limited, so it is necessary to continue to research and develop new anti-corrosion fungicides.

Low-toxicity fungicides can reduce the harm to health and environmental pollution, and the toxicity of fungicides is usually judged by the acute oral LD50 value of rats. Since the operator is often in direct contact with the processing fluid, it is required that the fungicide does not irritate the skin at the concentration used. The concentration of formaldehyde released into the air by the widely used formaldehyde condensation fungicides must also be limited, and too high a concentration of formaldehyde gas is very toxic to the human body. With the deepening of the research on fungicides, the restrictions on them are becoming more and more strict, such as requiring that they do not cause genetic harm to the human body and do not cause cell lesions.